For a professional motorcycle shop that will not be deal with cars and needs something smaller than a 12", you’ll need a motorcycle tire changer or a regular tire changer with an added adapter for motorcycle tires.

If you are going to purchase a tire changer for your shop, you should know what kind of tire changer will fit you best. Here are some suggestions from JINGJIA AUTO EQUIPMENT CO., LTD..

What is the size of the wheel that you dealing with the most?

Generally, we separate the tire in three kinds by the size. Motorcycle, regular and truck. When looking for a tire changer check the size of clamping first to ensure it fits the size of tires you’ll be working with.

For a professional motorcycle shop that will not be deal with cars and needs something smaller than a 12", you’ll need a motorcycle tire changer or a regular tire changer with an added adapter for motorcycle tires.

Our regular tire changers offer 12"-26" wheel size, with motorcycle adaptor.

For a truck repairing shop or you own a trucking business, you will need the heavy duty special truck tire changer for those bigger tires and wheels. Most big truck tire changers ranger from 14"- 56".

The size of wheel for our regular tire changer is 12"-26", if you find a tire changer from any websites that the price is lower, go to the clamping size then you will find out the differences, and for the larger wheel and tire, your tire changer must have longer cabinet and larger turn table, which means the machine size will be larger too.

So, when looking for a tire changer check the size of clamping first to make sure your getting the right fit for your needs.

Our regular tire changer wheel size is 12"-26". When purchasing a tire changer the size of clamping is one of the first thing to look at.

Are you going to deal with some run-flat tires and low profile tires?

You might have a hard time to dealing with the run-flat tires and low profile tires, it will be hard for the worker to pull the tire over bead on the demount head, and they should always be careful cause it requires for huge physical human power, so it might cause the worker injured or the wheel injured, either way, loss of money. Also, these “hard to mount” tire will cost you more time on it, lower the working efficiency.

Our help arms have been designed for handling the run-flat and low profile tires. The patented right side arm will help you to fully lubricate the tire, make it much easier to insert the bar and mount the tire, and nylon roller will fully protect the wheel from scratches.

Our left side help arm will provide a fully assist to clamp the wheel from outside by the center hole pressing function. The dish part can lift the tire when you demount the lower tire. The 360° pressing arm will make the mounting easier even for the fun flat and low profile tire, and also it provides the pressure on the opposite side of the demounting point, so it will be easier to pull the tire over bead.

So, when you choose a tire changer for the safety need and efficient need, especially for the run flat, low profile and “hard to do”tire, you will need the tire changer with some assist arm.

If you are finding professional tire changers, you can browse our website--www.chinapuli.com since we are tire changer manufacturer with decades of R&D experience.

2016年11月22日星期二

2016年11月20日星期日

2016年11月17日星期四

How to Use a PL-6097IT Tire Changer

| JINGJIA AUTO EQUIPMENT CO., LTD. offers tire changers including PL-6097IT

Tire Changer from leading manufacturers. Visit us for inventory blowouts on

tire changing equipment and other automotive shop equipment. Puli’s Tire changing machines come in several different styles. The most commonly used machine is the PL-6097IT Tire Changer which runs on air pressure. This machine has two pedals. One is for breaking the bead of the tire and removing the tire from the rim. It breaks both sides of the tire at the same time. The other pedal is used to inflate the tire. Always be cautious and wear safety glasses when operating any tire changing machine. Instructions 1,Place the rim on the machine with the locking stub coming through the center hole in the rim. Place the rim valve stem side up. 2,Place the locking cap on the locking stub and spin the cap until it is snug so the rim cannot move. 3,Place the upper bead breaker on the outer edge of the rim but do not let it rest on the rim. 4,Depress the foot pedal and break the bead of the tire. Once bead is broken move the upper bead breaker arm out of the way and return it to its original position. 5,Use soapy water as a lubricant on the outer bead of the tire. Insert the bead spoon into the tire. While pushing down on the opposite side of the tire pull the spoon back and lock the spoon onto the stub lock. Hold it firmly and press the pedal. The spoon will start turning, pushing the bead of the tire out. Repeat this step for the back bead. Remove the tire. 6,Place the new tire flat on the rim; lubricate both beads of the tire and push as much of the tire as you can onto the rim. Flip the tire spoon around and rest on the rim and lock the spoon on the stub. 7,Press the pedal and the spoon will force the tire onto the rim. Repeat this process for the outer bead. 8, Attach the air hose to the valve stem to begin pumping up the tire. Press the other pedal to the floor and hold it until the tire begins to pump up. Keep your hands clear of the rim while the tire inflates. The maximum pressure should be indicated on the side wall of the tire. |

2016年11月14日星期一

When buying Any Puli® Tire Changer, You’re also getting a Motorcycle Tire Changer

You can convert any Puli® tire changer into a motorcycle tire changer.

Obtaining a motorcycle tire changer for your tire service center or repair shop has never been so easy. When you purchase any Puli® tire changer you can add on a set of motorcycle adapters, the adapters attach easily to the tire changer and convert it to use with motorcycle tires. All Puli® tire changer models are user friendly, efficient, durable, and powerful enough to handle your volume of tire and wheel sales.

How Many Tire Changers Does Your Shop Need to Change Motorcycle Tires?

Keep in mind that the number of tires you can change with your Puli® motorcycle tire changer is directly related to the volume of business your shop experiences. If you are a full service tire and wheel sales and service center, it is better to have several tire changers accessible at all times to keep your flow of customer traffic moving.Unless you deal in a large amount of motorcycle tire and wheel sales, it is often sufficient to have a single set of motorcycle adapters. However, if you have a higher amount of motorcycle customers, then having more than one set of flip adapters on hand is recommended.

To learn more about Puli® tire changers, as well as other Puli® brand equipment such as wheel balancers, or nitrogen generators for your shop. Please explore our website www.chinapuli.com. We are here to provide assistance and support in helping you choose the best equipment which fits your needs.

Obtaining a motorcycle tire changer for your tire service center or repair shop has never been so easy. When you purchase any Puli® tire changer you can add on a set of motorcycle adapters, the adapters attach easily to the tire changer and convert it to use with motorcycle tires. All Puli® tire changer models are user friendly, efficient, durable, and powerful enough to handle your volume of tire and wheel sales.

How Many Tire Changers Does Your Shop Need to Change Motorcycle Tires?

Keep in mind that the number of tires you can change with your Puli® motorcycle tire changer is directly related to the volume of business your shop experiences. If you are a full service tire and wheel sales and service center, it is better to have several tire changers accessible at all times to keep your flow of customer traffic moving.Unless you deal in a large amount of motorcycle tire and wheel sales, it is often sufficient to have a single set of motorcycle adapters. However, if you have a higher amount of motorcycle customers, then having more than one set of flip adapters on hand is recommended.

To learn more about Puli® tire changers, as well as other Puli® brand equipment such as wheel balancers, or nitrogen generators for your shop. Please explore our website www.chinapuli.com. We are here to provide assistance and support in helping you choose the best equipment which fits your needs.

2016年11月8日星期二

Invest in an Affordable, Yet High Quality Tire Changer

If you want to service a wide range of vehicles at your repair shop, service center, or tire shop, you need to have right kinds of equipment and tools on hand. It is just as important to invest in high quality equipment and tools, which will last longer and give you a better return on your investment. For example, you want to invest in a new tire changer, but you are unsure of which brand would be the best.

One thing to remember is price does not always reflect quality. It is possible to find high quality equipment at reasonable price, like a Puli PL-1291IT Tire Changer. You can be confident in its’quality because Puli® manufacturing factory source only the highest quality parts and materials to assemble our products.

Other manufacturers normally source their parts and components from the lowest bidders and have very little control over what they receive, which can lead to a lower quality tire changer. To learn more about Puli® tire changers and other products for your garage, feel free to contact us directly, here at JINGJIA AUTO EQUIPMENT CO., LTD., as we are the exclusive distributor for Puli brand automotive equipment. www.chinapuli.com

One thing to remember is price does not always reflect quality. It is possible to find high quality equipment at reasonable price, like a Puli PL-1291IT Tire Changer. You can be confident in its’quality because Puli® manufacturing factory source only the highest quality parts and materials to assemble our products.

Other manufacturers normally source their parts and components from the lowest bidders and have very little control over what they receive, which can lead to a lower quality tire changer. To learn more about Puli® tire changers and other products for your garage, feel free to contact us directly, here at JINGJIA AUTO EQUIPMENT CO., LTD., as we are the exclusive distributor for Puli brand automotive equipment. www.chinapuli.com

2016年11月6日星期日

Puli PL-1100 Wheel Balancer

| At JINGJIA AUTO EQUIPMENT CO., LTD., we sell the best automotive products for your auto service shops and garages. Today’s spotlight is our Puli PL-1100 wheel balancer, the Puli PL-1100 is the most popular Unite wheel balancer that we sell. The low price and dependability of the PL-1100 make it the backbone of our entire Eco line of wheel balancers. Visit http://www.chinapuli.com/Basic-Class-Wheel-Balancer/PL-1100-Wheel-Balancer.html for more information on PL-1100 wheel balancer and other products for your automotive needs! |

2016年11月2日星期三

Puli Tyre Changers Is Suitable for Any tires

Our tire changers can handle your normal small car rims all the way up to large semi truck rims. Our tire machines can also handle low profile, run flat, aluminum and alloy wheels. If you purchase the ATV or Motorcycle adapter set you will be able to change almost any tire from any vehicle on the market. Buy one of our tire changers now and expand your business to realize profits you never had before.

http://chinapuli.com/Tyre-Changer/

http://chinapuli.com/Tyre-Changer/

2016年10月31日星期一

Tire Changers

| Shop our complete line of tire changers. Puli tire machines are built to

handle the toughest tires, the most delicate wheels, and even large and

rugged truck tires. Shop Puli tire changers when you're looking for the right

technology at the right price. http://chinapuli.com/Tyre-Changer/ |

2016年10月26日星期三

Correct wheel alignment

Correct wheel alignment improves road holding and maximises the life of tyres. Aligning the front two wheels resolves alignment issues for most vehicles. Not all cars can have the rear wheels adjusted so any additional requirement for all four wheels to be adjusted needs to be discussed with the auto service centre once the initial check is done.

What is wheel alignment?

Wheel alignment (or 'tracking') refers to the angle and direction at which the tyres are set.

Hitting kerbs or driving at speed through a pothole can result in wheel misalignment. Poorly aligned tyres can affect road holding, increase fuel consumption and decrease the life of your tyres.

How do I know if my wheels need to be aligned?

Watch out for these classic signs of wheel misalignment:

Uneven tyre wear

Steering wheel pull (the steering wheel pulling to the left or right when driving on an even surface)

How can I get my wheels aligned?

If you spot the signs of misaligned wheels, come to auto service center and the technicians there will correct the problem.

If you are finding professional wheel alignment equipments, pls visit http://www.chinapuli.com/Wheel_aligner/.

What is wheel alignment?

Wheel alignment (or 'tracking') refers to the angle and direction at which the tyres are set.

Hitting kerbs or driving at speed through a pothole can result in wheel misalignment. Poorly aligned tyres can affect road holding, increase fuel consumption and decrease the life of your tyres.

How do I know if my wheels need to be aligned?

Watch out for these classic signs of wheel misalignment:

Uneven tyre wear

Steering wheel pull (the steering wheel pulling to the left or right when driving on an even surface)

How can I get my wheels aligned?

If you spot the signs of misaligned wheels, come to auto service center and the technicians there will correct the problem.

If you are finding professional wheel alignment equipments, pls visit http://www.chinapuli.com/Wheel_aligner/.

2016年10月18日星期二

Puli’s Different Types of Wheel Balancer

GUANGZHOU JINGJIA AUTO EQUIPMENT CO., LTD.-Puli brand is the world leader in wheel balancers. Learn about Puli’s different types of wheel balancing machines and equipment here.

http://www.chinapuli.com/Wheel_Balancer/

http://www.chinapuli.com/Wheel_Balancer/

2016年10月16日星期日

Our Two Post Lifts

We offer our customers an excellent quality range of Two Post Lift, which are manufactured from high grade quality raw materials.

Our Two Post Lifts are widely known for their durability and quality. For more details, pls feel free to visit http://www.chinapuli.com/Two-Post-Lift/. Welcome for your inquiry.

2016年10月14日星期五

What is the best wheel balancer for tire shops?

The wheel balancer you put in your tire shop is totally dependent on the type of vehicles you service. Puli Products offers three units that reflect the different needs of tire shops across the country. If you mainly service cars, light trucks and SUVs, then you probably don’t need the largest unit we offer. Likewise, if

your tire shop services commercial trucks on a regular basis, we have a wheel

balancer to work around the clock on some of the largest commercial truck tires

on the market. We’d like to offer you a quick breakdown of the three wheel

balancers we offer. Think of this as your Puli Products wheel balancer cheat

sheet, a quick reference guide to help you save time on our site.

PL-1890: Elegance with 7 Balancing Modes

The PL-1890 wheel balancer will balance tires up to 24" in diameter, quickly and accurately. This is one of the best wheel balancers for your tire shop. An easy-

to-read 17”LCD monitor, 3D animation interface gives you fast readings and helps you accurately adjust the balance of a wide variety of wheels. While it looks

similar to other wheel balancers, Puli Products takes pride in the look and feel of our equipment. The hardware, electrical components and readouts on this unit

are as durable as the rest of the machine. We stand by this model wheel balancer as the industry standard-bearer in quality.

PL-1823: Higher Class Deluxe design

High precision main shaft with strict heat treatment process makes sure

repeated measuring accuracy. With data automatic measurement function.

Bigger machine cabinet with thicker material. Bigger and higher steel bottom stand can protect inside chips from moisture and coldness so as to make machine running stable.

Tracking sticking balancing mode can locate weights precisely and rapidly, and

avoid adjusting position repeatedly. Especially use to balance the new type high

class wheel which only be balance with sticking weights.

PL-1150: Basic Series, Easy and safety operation

High precision main shaft with strict heat treatment process makes sure

repeated measuring accuracy.

High stable and high accurate computer chip. With self-calibration and

self-diagnosis fuctions.

LED light & Digital display.

With 5 balancing modes and OPT function. Extended measuring scale can

measure rims from10" to 24".

For more wheel balancer details, pls visit our website http://www.chinapuli.com/Wheel_Balancer/.

your tire shop services commercial trucks on a regular basis, we have a wheel

balancer to work around the clock on some of the largest commercial truck tires

on the market. We’d like to offer you a quick breakdown of the three wheel

balancers we offer. Think of this as your Puli Products wheel balancer cheat

sheet, a quick reference guide to help you save time on our site.

PL-1890: Elegance with 7 Balancing Modes

The PL-1890 wheel balancer will balance tires up to 24" in diameter, quickly and accurately. This is one of the best wheel balancers for your tire shop. An easy-

to-read 17”LCD monitor, 3D animation interface gives you fast readings and helps you accurately adjust the balance of a wide variety of wheels. While it looks

similar to other wheel balancers, Puli Products takes pride in the look and feel of our equipment. The hardware, electrical components and readouts on this unit

are as durable as the rest of the machine. We stand by this model wheel balancer as the industry standard-bearer in quality.

PL-1823: Higher Class Deluxe design

High precision main shaft with strict heat treatment process makes sure

repeated measuring accuracy. With data automatic measurement function.

Bigger machine cabinet with thicker material. Bigger and higher steel bottom stand can protect inside chips from moisture and coldness so as to make machine running stable.

Tracking sticking balancing mode can locate weights precisely and rapidly, and

avoid adjusting position repeatedly. Especially use to balance the new type high

class wheel which only be balance with sticking weights.

PL-1150: Basic Series, Easy and safety operation

High precision main shaft with strict heat treatment process makes sure

repeated measuring accuracy.

High stable and high accurate computer chip. With self-calibration and

self-diagnosis fuctions.

LED light & Digital display.

With 5 balancing modes and OPT function. Extended measuring scale can

measure rims from10" to 24".

For more wheel balancer details, pls visit our website http://www.chinapuli.com/Wheel_Balancer/.

2016年10月11日星期二

Wheel balancers from Puli

Wheel balancers from Puli offer superior reliability, repeatability and precision. A wheel balancer from Puli means you will get rugged construction and excellent quality just like all our wheel service equipment.

You can browse our website for more details. http://www.chinapuli.com/Wheel_Balancer/

2016年10月9日星期日

Selection of the Best 2 Post Lifts Online

If you're looking for car lifts, truck lifts, auto lifts - Puli car lift offers a selection of the best 2 post lifts that you can buy online.

2016年10月7日星期五

Annual Car Lift Inspections

CAR LIFT INSPECTIONS MUST BE PREFORMED REGULARLY TO ENSURE SAFETY.

You load up the car lift with a very heavy car, raise it up and then stand under it. It is VITALLY important that you take all the precautions you can to ensure you, and your staff, is safe.

You should get your lift inspected annually by a qualified lift inspector. You can find some qualified inspectors from the lift’s manufacturer or from the Automotive Lift Institutes online database. They can inspect any style and brand of lift.

What happens during the annual car lift inspection? During the inspection, the inspector is looking to confirm that all of the lift’s components are in place and in working order. Most importantly, that your lift is SAFE.

Examining all accessible structural components, including welds, for any evidence of overloading, misuse or abuse.

Examining electrical components and wiring.

Checking the lift controls to ensure accessibility, an unobstructed view of the lift and an automatic return to the neutral or “off ” position when released.

Locating appropriate lift documentation, safety instructions, vehicle-lifting information, lift safety labeling and capacity labeling.

Confirming adequate clearances around the lift.

Checking all fastening devices for tightness and proper fit.

An annual lift inspection includes a thorough evaluation of the entire vehicle lift.

Checking the lowering speed over the full down travel of the lift.

Operating the lift through its full cycle and checking the operation of the positive stop. Checking to see if the lift locks engage in the fully extended position.

Checking all lubrication points for cleanliness, integrity of fitting and presence of lubricant.

Checking all chains and cables for excessive slack.

Checking all potential pinch points. The standard is just the starting point. Every lift manufacturer should provide specific directions for inspecting each of its lifts. ALI Certified Lift Inspectors are qualified to inspect any brand or model of vehicle lift.

Please visit http://www.chinapuli.com/Lift/ for more car lift information.

2016年9月28日星期三

Car Lift Maintenance: Check it Every Day

I met a gentleman the other day that was 96 years young! He was surprisingly

agile and swift on his feet. He had few wrinkles and looked really good for his

age! I was really impressed and thought he wasn’t a day past 70. That got me to

thinking about ‘maintenance’. If I exercise, take care of myself, eat right

and stress less…. Will that help me to age just as gracefully?

There are Puli car lifts out there that have been doing their job for decades and

still run like the day they were installed. They have aged well, with the right

maintenance and care. Do you know how to maintain your lift so it will run like

new for many years? Luckily, it’s easier to know how to help your lift age well

…. my wrinkles, not so much!

Perhaps the most important car lift maintenance is to adjust the cables. Over

time, the cables stretch and if not adjusted, a cable can jump a pulley or cause

the lift to rise unevenly. Each cable should have about .5” of deflection

(should not move more than .5”). This is true for a two-post or four-post lift.

Adjustments are very simple to do and the steps are specific in the manual

provided with your lift. Please look that over for instructions on how to adjust

your cables.

Next is lubrication on your lift. Chain rollers, cable pulleys, safety latches

and carriage tracks inside the towers. We recommend white lithium grease. You

should do this weekly.

A simple walk around your car lift for a safety check is easy, yet rarely done.

Make sure there is nothing in the tracks or carriage (shop rags, tools,

cardboard, etc.) that may cause the machine to bind up. Run the lift up and down

without a load and ensure the safety features are in working order.

In addition to regular in-house inspections, the standard requires that all

vehicle lifts be inspected at least annually by a “qualified lift inspector.” A

lift inspection is a thorough evaluation of the operating mechanism(s), safety

system(s), maintenance, structural integrity and field modifications of a

particular lift in order to identify any risks which may affect the ability of

that lift to operate in a safe and reliable manner.

– Lift cables normally require replacement every four to five years.

– Lift cables should be replaced if you see three or more broken wires in one

strand.

– Replace the cables if you see: corrosion or rusting on the wires or ends,

kinking, crushed

areas, cutting, spreading, a cable core protruding, or any other abnormality.

– If any cable defects are found the lift should be shut down immediately until

the defective

cable(s) have been replaced.

– Cables and other lift parts should be kept free of corrosive agents, solvents,

and road

salt. If such agents are spilled or splashed on any lift component, immediately

rinse and

wipe down with a clean rag.

– Spray cables every three months with Penetrating Oil and wipe down. Failure to

keep

cables free of corrosive agents will lead to reduced service life, cable failure,

etc. which

could result in property damage and/or personal injury.

Every. Single. DAY.

– Give the lift a quick once-over before using it. Check for any obvious leaks

or defects.

Inspect cables, hoses and chains for any sign of wear.

– Verify lift is operating properly, rising smoothly and levelly and all locking

mechanisms for

the arms and carriages are working.

Every. Single. WEEK.

– Lubricate all chain rollers and cable pulleys. Grease the carriage tracks

inside the towers.

– Check all nuts and bolts; tighten where necessary.

– After the first week, check cable tension and adjust as necessary. Check every

6 months

after.

Every. Single. MONTH.

– Check and lubricate all safety mechanisms; ensure they are in proper working

order.

Replace any worn or defective parts.

– Check and tighten anchor bolts as necessary.

– Inspect all moving parts; replace any worn or defective parts.

professional automotive repair car lifts manufacturer: www.chinapuli.com

agile and swift on his feet. He had few wrinkles and looked really good for his

age! I was really impressed and thought he wasn’t a day past 70. That got me to

thinking about ‘maintenance’. If I exercise, take care of myself, eat right

and stress less…. Will that help me to age just as gracefully?

There are Puli car lifts out there that have been doing their job for decades and

still run like the day they were installed. They have aged well, with the right

maintenance and care. Do you know how to maintain your lift so it will run like

new for many years? Luckily, it’s easier to know how to help your lift age well

…. my wrinkles, not so much!

Perhaps the most important car lift maintenance is to adjust the cables. Over

time, the cables stretch and if not adjusted, a cable can jump a pulley or cause

the lift to rise unevenly. Each cable should have about .5” of deflection

(should not move more than .5”). This is true for a two-post or four-post lift.

Adjustments are very simple to do and the steps are specific in the manual

provided with your lift. Please look that over for instructions on how to adjust

your cables.

Next is lubrication on your lift. Chain rollers, cable pulleys, safety latches

and carriage tracks inside the towers. We recommend white lithium grease. You

should do this weekly.

A simple walk around your car lift for a safety check is easy, yet rarely done.

Make sure there is nothing in the tracks or carriage (shop rags, tools,

cardboard, etc.) that may cause the machine to bind up. Run the lift up and down

without a load and ensure the safety features are in working order.

In addition to regular in-house inspections, the standard requires that all

vehicle lifts be inspected at least annually by a “qualified lift inspector.” A

lift inspection is a thorough evaluation of the operating mechanism(s), safety

system(s), maintenance, structural integrity and field modifications of a

particular lift in order to identify any risks which may affect the ability of

that lift to operate in a safe and reliable manner.

– Lift cables normally require replacement every four to five years.

– Lift cables should be replaced if you see three or more broken wires in one

strand.

– Replace the cables if you see: corrosion or rusting on the wires or ends,

kinking, crushed

areas, cutting, spreading, a cable core protruding, or any other abnormality.

– If any cable defects are found the lift should be shut down immediately until

the defective

cable(s) have been replaced.

– Cables and other lift parts should be kept free of corrosive agents, solvents,

and road

salt. If such agents are spilled or splashed on any lift component, immediately

rinse and

wipe down with a clean rag.

– Spray cables every three months with Penetrating Oil and wipe down. Failure to

keep

cables free of corrosive agents will lead to reduced service life, cable failure,

etc. which

could result in property damage and/or personal injury.

Every. Single. DAY.

– Give the lift a quick once-over before using it. Check for any obvious leaks

or defects.

Inspect cables, hoses and chains for any sign of wear.

– Verify lift is operating properly, rising smoothly and levelly and all locking

mechanisms for

the arms and carriages are working.

Every. Single. WEEK.

– Lubricate all chain rollers and cable pulleys. Grease the carriage tracks

inside the towers.

– Check all nuts and bolts; tighten where necessary.

– After the first week, check cable tension and adjust as necessary. Check every

6 months

after.

Every. Single. MONTH.

– Check and lubricate all safety mechanisms; ensure they are in proper working

order.

Replace any worn or defective parts.

– Check and tighten anchor bolts as necessary.

– Inspect all moving parts; replace any worn or defective parts.

professional automotive repair car lifts manufacturer: www.chinapuli.com

2016年9月20日星期二

PULI INTRODUCES ECO 60 SERIES TIRE CHANGER SPECIFICATION AND FEATURES

GUANGZHOU JINGJIA AUTO EQUIPMENT CO., LTD. is proud to present to our customers that we have new internationally patented Eco 60 series tire changers.

The new gear box received national patent in the year 2013, (patent no. is 201320507624.3) and received international innovation patent, (patent no. is PCT/CN2013/085959)

In 2014, the new machine body cabinet received a UTILITY model patent. (patent no. 201420205859.1)

1.Gear Box

Nowadays all tire changers have reduction boxes, with worm disk’s and rod transmission’s, which wastes about 30% from total power.

With an additional 20% power loss from the driving belt, the real power being produced by the turntable is only about 50%. Tests show torque produced at 1100N.m for the turntable, from a 0.75KW motor at 220V.

GUANGZHOU JINGJIA AUTO EQUIPMENT CO., LTD., has many years of manufacturing experience with tire changers and has successfully developed a new integrated gear box, consisting of a redesigned motor and reduction gearing. The new patent gear box adopts a high performance gear transmission and high strength gears, as to greatly reduce power loss and increase gear box life span. The redesigned integration of motor and gears reduces the amount of power loss from the driving belt.

Internationally patented integrated reduction gear box

Features of the new gear box :

The new gear box provides 50% more power than previous models.

The highly efficient direct gear transmission has about 99% of efficient power usage, which means only 1% of power is lost during operation. Tests show turntable torque at 1200N.m from a 0.35KW motor at 110V.

Real torque output is increased while power usage is only half that of the previous motor. For an average 8-hour work day. The previous 0.75KW motor consumes 6KWH power, whereas the new gear box with the 0.35KW motor only consumes 2.8KWH power. So annually, the new model tire changer saves 1168KWH power [365*(6-2.8) =1168]

Puli 60 series tire changers featured configuration:

Integrate power saving and eco gear box

Aluminum bead breaking cylinder (φ200)

Aluminum 5-way valves

Aluminum rotary valve

Aluminum exhaust valve (equipped with built-in bead blaster system )

For more detialed information of our eco 60 series tire changers, please feel free to explore out website http://www.chinapuli.com/Tyre-Changer/.

The new gear box received national patent in the year 2013, (patent no. is 201320507624.3) and received international innovation patent, (patent no. is PCT/CN2013/085959)

In 2014, the new machine body cabinet received a UTILITY model patent. (patent no. 201420205859.1)

1.Gear Box

Nowadays all tire changers have reduction boxes, with worm disk’s and rod transmission’s, which wastes about 30% from total power.

With an additional 20% power loss from the driving belt, the real power being produced by the turntable is only about 50%. Tests show torque produced at 1100N.m for the turntable, from a 0.75KW motor at 220V.

GUANGZHOU JINGJIA AUTO EQUIPMENT CO., LTD., has many years of manufacturing experience with tire changers and has successfully developed a new integrated gear box, consisting of a redesigned motor and reduction gearing. The new patent gear box adopts a high performance gear transmission and high strength gears, as to greatly reduce power loss and increase gear box life span. The redesigned integration of motor and gears reduces the amount of power loss from the driving belt.

Internationally patented integrated reduction gear box

Features of the new gear box :

The new gear box provides 50% more power than previous models.

The highly efficient direct gear transmission has about 99% of efficient power usage, which means only 1% of power is lost during operation. Tests show turntable torque at 1200N.m from a 0.35KW motor at 110V.

Real torque output is increased while power usage is only half that of the previous motor. For an average 8-hour work day. The previous 0.75KW motor consumes 6KWH power, whereas the new gear box with the 0.35KW motor only consumes 2.8KWH power. So annually, the new model tire changer saves 1168KWH power [365*(6-2.8) =1168]

Puli 60 series tire changers featured configuration:

Integrate power saving and eco gear box

Aluminum bead breaking cylinder (φ200)

Aluminum 5-way valves

Aluminum rotary valve

Aluminum exhaust valve (equipped with built-in bead blaster system )

For more detialed information of our eco 60 series tire changers, please feel free to explore out website http://www.chinapuli.com/Tyre-Changer/.

2016年9月18日星期日

The Benefits of Wheel Alignment

Proper wheel alignment is extremely important to protect tire investment and

tire life, maximize fuel economy and stop safely in wet weather conditions.

Proper alignment also maximizes fuel economy. Vehicles with wheel alignment

conditions can suffer a decrease in fuel efficiency by up to 7%. As vehicle

manufacturers equip more vehicles with on-board driver-assist systems, such as

electronic stability control, parking assist, traction control and more, an

increasing number of OEM's now require a steering system reset during alignment

service. It is important to have an alignment system that can reset all

alignment-related sensors during alignment service.

For more information on Puli's Wheel Aligners, click here :http://www.chinapuli.com/Wheel_aligner/.

2016年9月13日星期二

Change Car Tires with Puli Automatic Tire Changer

The Puli PL-1221 is a full-automatic pneumatic tilting column, high perfomance

tire changer that simplifies the challenging job of tire changing. Designed for

biggger and wider variouse new tyres, specialty shops and dealerships, the PL-

1221 can change varieties of tires, including some low profile tires.

Although the PL-1221 is loaded with innovative features, it is easy to operate,

vertical arm positioning automatically and synchronous pneumatic locked at any

optional position; clamping jaws are totally one step die casting; max working clamping 24". The PL-1221 tire changer will prove to be a positive game-changer for shop performance, productivity and most importantly, the basis series.

For more details, pls feel free to refer our website http://www.chinapuli.com/Tilting-Arm-Tire-Changer-Basic/PL-1221-Tyre-Changer.html.

2016年9月11日星期日

Puli Wheel Balancers

Puli wheel balancers offer customers superior performance and value. The quality performance from Puli wheel balancers ensure tires are balanced right the first time, every time! Our balancers provide simple, accurate and fast results to meet the needs of today’s wheel service technician.

http://www.chinapuli.com/Wheel_Balancer/

http://www.chinapuli.com/Wheel_Balancer/

2016年9月8日星期四

The 120th Canton Fair Invitation

Dear Customer,

We are pleased to inform you that our company will be exhibiting at the the 120th canton fair to present our new and exciting lubrication equipment and garage equipment in 15-19 Oct, 2016.

We invite you to join us at our booth and have a friendly chat.

It’s a great opportunity for us knowing each other better. You can learn what

product and service we can offer you. I am sure you will find something

interesting there.

Your esteemed presence would be an honor!

We are pleased to inform you that our company will be exhibiting at the the 120th canton fair to present our new and exciting lubrication equipment and garage equipment in 15-19 Oct, 2016.

We invite you to join us at our booth and have a friendly chat.

It’s a great opportunity for us knowing each other better. You can learn what

product and service we can offer you. I am sure you will find something

interesting there.

Your esteemed presence would be an honor!

2016年9月6日星期二

Puli Introduces Higher Class Series 2 Years Warranty PL-1209IT Tire Changer

Semi-automatic swing arm PL-1209IT Tire Changer

Detailed information, pls refer to the picture or our website http://www.chinapuli.com/Swing-Arm-Tire-Changer-Upgraded/PL-1209IT-Tyre-Changer.html.

Detailed information, pls refer to the picture or our website http://www.chinapuli.com/Swing-Arm-Tire-Changer-Upgraded/PL-1209IT-Tyre-Changer.html.

2016年9月1日星期四

Hot Sale PL-2900 Truck Tyre Changer

| Hot Sale PL-2900 Truck Tyre Changer |

For more product details, pls refer to our website http://www.chinapuli.com/Truck-Tire-Changer/ |

2016年8月30日星期二

Puli PL-M02 Motorcycle Lift — Get Your Motorcycle Ready to Ride!

If you own a motorbike and you like to do your own maintenance … or you want to be able to keep it looking great…. you need the Puli PL-M02 Motorcycle Lift!

The Puli PL-M02 Motorcycle Lift is a 1,102 lb capacity, electro hydraulic, easy-to-use lift for motorcycles, snowmobiles, ATVs, jet skis and other small recreational vehicles.

The extra-large platform has a 47″ working height and a removable rear wheel access plate for easy access. This lift comes with a secure wheel vise. Moving this lift around your garage is effortless with trouble-free wheels to get it moving.

1,102 lb. lifting capacity

Removable steel ramp

Removable rear wheel access plate

Extra-large platform 47″ working height

For those who want to do more service work on their motorcycle, Puli has a Motorcycle Tire Changer and a Motorcycle Wheel Balancer to make it easy. You can get everything you need in the Puli--www.chinapuli.com.

The Puli PL-M02 Motorcycle Lift is a 1,102 lb capacity, electro hydraulic, easy-to-use lift for motorcycles, snowmobiles, ATVs, jet skis and other small recreational vehicles.

The extra-large platform has a 47″ working height and a removable rear wheel access plate for easy access. This lift comes with a secure wheel vise. Moving this lift around your garage is effortless with trouble-free wheels to get it moving.

1,102 lb. lifting capacity

Removable steel ramp

Removable rear wheel access plate

Extra-large platform 47″ working height

For those who want to do more service work on their motorcycle, Puli has a Motorcycle Tire Changer and a Motorcycle Wheel Balancer to make it easy. You can get everything you need in the Puli--www.chinapuli.com.

2016年8月22日星期一

Tire Changers: Breaking it Down

At the top of the list, with oil changes and brakes, changing and repairing tires is one of the most common jobs at your local repair shop. A good tire changer will, with regular maintenance and some repairs, last for many years.

Times are a changing in the tire-changing world! The days of easy steel rims and regular valve stems are fast disappearing. These days there are “soft” aluminum rims, tires with stiff sidewalls and TPMS (tire pressure monitoring system) valve stems that, if serviced improperly, can break. Keep this in mind when shopping for a new tire changer.

When you’re in the market for a tire changer, it’s hard to differentiate between all of the different brands out there, each company trying to put their best foot forward in a bid to win over your trust and loyalty. Each brand then has a variety of tire changer models, fashioned to meet the needs of specific niches. Here’s how you can easily select the right changer for you from Puli Equipment.

Size Matters! What type and size of wheels do you want to work on?

The size of the wheel: Before you shop for a tire changer, you need to know what size tires you will be changing. Look at the rim diameter of the tires to be changed; 20 to 24 inch diameter is the common measurement of most wheels. If you want to go smaller, like motorcycles …. Or larger, like truck tires … that will determine if a different changer is needed.

The type of wheel: Light trucks will utilize a different tire changer from heavy-duty trucks. There are also shops that specialize in run flat tires or low profile wheels. Such tires require special tire changers because the ordinary models may not be able to handle too well.

The style tire shop that you are: Do you do a lot of tires? Are you just getting started? Do you want to be able to work on specialty tires or large truck-tires? The tire changer you choose will determine the style of shop you are.

With these factors in mind, we now need to look at the different types of tire changers available from Puli. Each style has been designed for specific needs. Now that you know what type of tires you want to work on, here is how to easily find the one that fits.

http://www.chinapuli.com/Tyre-Changer/

Times are a changing in the tire-changing world! The days of easy steel rims and regular valve stems are fast disappearing. These days there are “soft” aluminum rims, tires with stiff sidewalls and TPMS (tire pressure monitoring system) valve stems that, if serviced improperly, can break. Keep this in mind when shopping for a new tire changer.

When you’re in the market for a tire changer, it’s hard to differentiate between all of the different brands out there, each company trying to put their best foot forward in a bid to win over your trust and loyalty. Each brand then has a variety of tire changer models, fashioned to meet the needs of specific niches. Here’s how you can easily select the right changer for you from Puli Equipment.

Size Matters! What type and size of wheels do you want to work on?

The size of the wheel: Before you shop for a tire changer, you need to know what size tires you will be changing. Look at the rim diameter of the tires to be changed; 20 to 24 inch diameter is the common measurement of most wheels. If you want to go smaller, like motorcycles …. Or larger, like truck tires … that will determine if a different changer is needed.

The type of wheel: Light trucks will utilize a different tire changer from heavy-duty trucks. There are also shops that specialize in run flat tires or low profile wheels. Such tires require special tire changers because the ordinary models may not be able to handle too well.

The style tire shop that you are: Do you do a lot of tires? Are you just getting started? Do you want to be able to work on specialty tires or large truck-tires? The tire changer you choose will determine the style of shop you are.

With these factors in mind, we now need to look at the different types of tire changers available from Puli. Each style has been designed for specific needs. Now that you know what type of tires you want to work on, here is how to easily find the one that fits.

http://www.chinapuli.com/Tyre-Changer/

2016年8月18日星期四

Notice: upgrade Balancers from 32 cog raster to 64/128cog raster

| From October to December of 2016, we will upgrade Wheel Balancer for much higher precision. Below are the details: 1.Upgrade Complete shaft 32 cog raster to 64 cog raster Balancers model shown in below: PL-1150,PL-1152,PL-1100,PL-1120,PL-1800,PL-1820,PL-1821,PL-1823, PL-1828, PL-1829,PL-1897 2.Upgrade Complete shaft 32 cog raster to 128 cog raster Balancers model shown in below: PL-6570,PL-6572,PL-6573,PL-6574,PL-65729WR,PL-6575WR,PL-6579WR,PL-6881, PL-6882, PL-6883,PL-6883WR, PL-6828,PL-6885WR 3.As well, we will also upgrade the computer board of the balancers. The new computer board will be common to all models as 32/64/128cog raster balancers. For the customers’ first new balancers order after upgrade, we will send 1pc new computer board per 10 balancers for future continuous service after sales. Note:The current old 32cog raster computer board cannot be used to 64/128cog raster balancers. The new computer board will be in black color, and which can be used to all the balancers as 32/64/128 cog raster. If you looking for wheel balancer, pls feel free to browse our website http://www.chinapuli.com/Wheel_Balancer/ |

2016年8月16日星期二

Scissor Lift Safety Notes

Large platform profile scissor lift instruction & safety notes

General precautions

The operator and the maintenance fitter are required to observe the prescriptions of safety regulation in force in the country of installation of the lift.

Furthermore, the operator and maintenance fitter must:

-Always work in the stations specified and illustrated in this manual;

-Never remove or deactivate the guards and mechanical, electrical, or other types of safety devices;

-Read the safety notices placed on the machine and the safety information in this manual.

In the manual all safety notices are shown as follows:

Warning: indicates following operations that are unsafe and can cause minor injury to persons and damage the lift, the vehicle or other property.

Risk of electric shock: a specific safety notice placed on the lift in areas where the risk of electric shock is particularly high.

Risk and protection devices

For optimal personal safety and safety of vehicles, observe the following regulations:

-Do not enter the safety and safety of vehicles is being lifted.

-Be sure to lift only approved vehicles, never exceed the specified carrying capacity, maximum height, and projection (vehicle length and width);

-Make sure that there is no person on the platforms during up and down movements and during standing

General risks for lifting or descent

The following safety equipments are used to protect over loading or the possibility of engine failure.

In the condition of over loading, the over-falling valve will open and directly return oil to the oil tank.

Each bottom of oil cylinder is equipped with antiknock and locked valve(optional). When the oil pipe is burst in the circuit of hydraulic pressure, the relevant antiknock and locked valve will work and limit the speediness of platform.

Safety tooth and gear module are parts which guarantee the safety of personnel beneath the machine in failure condition of other protections.

So make sure the integrity of gear module and that the safety tooth has occluded completely.

There is nothing abnormal should be left on the safety modules to prevent safety gear from occlude normally.

Risk for extrusion

During up and down operations, personnel leave the said area without following the rule and instruction.

During up and down operations, no person is admitted to work beneath the movable parts of the lift, should work in the safe zone.

Risk of impact

Before the operator begins up and down movements, make sure that there are no personnel inside the danger zone. When, due to operational reasons, the lift is stopped at relatively low elevations (lower than 1.75m above the ground) personnel must be careful to avoid impact with parts of the machine not marked with special colors.

Risk of falling (vehicle)

This hazard may arise in the case of incorrect positioning of the vehicle on the platforms, overweight of the vehicle, or in the case of vehicles of dimensions that are not compatible with the capacity of the lift.

When the platform is being tested, the vehicle engine can not be turned on.

There is nothing should be placed on the lift-lowering area and the movable parts of the lift.

Risk of slipping

The floor caused by lubricant contamination of around the lift. The area beneath and immediately surrounding the lift and also the platforms must be kept clean. Remove any oil spills immediately.

Risk of electric shock

Risk of electric shock in areas of insulated and shattered electric equipments

Do not use jets of water, steam solvents or paint next to the lift, and take special care to keep such substances clear of the electrical control panel.

Risks related to appropriate lighting

The operator and the maintenance fitter must be able to assure that all the areas of the lift are properly and uniformly illuminate compliance with the laws in force in the place of installation.

During up and down operations, the operator should continually observe the lift and can operate it only in the position of operator. When lifting and lowering the vehicle, the cushion needs being put in the bottom of chassis.

The handling of safety devices is strictly forbidden. Never exceed the maximum carrying capacity of the lift, make sure the vehicles to be lifted have no load.

It is therefore essential to adhere scrupulously to all regulations regarding use, maintenance and safety contained in this manual.

High quality scissor lifts are on promotion now, detailed product information, pls refer to our website http://www.chinapuli.com/Lift/Scissor-Lift/.

General precautions

The operator and the maintenance fitter are required to observe the prescriptions of safety regulation in force in the country of installation of the lift.

Furthermore, the operator and maintenance fitter must:

-Always work in the stations specified and illustrated in this manual;

-Never remove or deactivate the guards and mechanical, electrical, or other types of safety devices;

-Read the safety notices placed on the machine and the safety information in this manual.

In the manual all safety notices are shown as follows:

Warning: indicates following operations that are unsafe and can cause minor injury to persons and damage the lift, the vehicle or other property.

Risk of electric shock: a specific safety notice placed on the lift in areas where the risk of electric shock is particularly high.

Risk and protection devices

For optimal personal safety and safety of vehicles, observe the following regulations:

-Do not enter the safety and safety of vehicles is being lifted.

-Be sure to lift only approved vehicles, never exceed the specified carrying capacity, maximum height, and projection (vehicle length and width);

-Make sure that there is no person on the platforms during up and down movements and during standing

General risks for lifting or descent

The following safety equipments are used to protect over loading or the possibility of engine failure.

In the condition of over loading, the over-falling valve will open and directly return oil to the oil tank.

Each bottom of oil cylinder is equipped with antiknock and locked valve(optional). When the oil pipe is burst in the circuit of hydraulic pressure, the relevant antiknock and locked valve will work and limit the speediness of platform.

Safety tooth and gear module are parts which guarantee the safety of personnel beneath the machine in failure condition of other protections.

So make sure the integrity of gear module and that the safety tooth has occluded completely.

There is nothing abnormal should be left on the safety modules to prevent safety gear from occlude normally.

Risk for extrusion

During up and down operations, personnel leave the said area without following the rule and instruction.

During up and down operations, no person is admitted to work beneath the movable parts of the lift, should work in the safe zone.

Risk of impact

Before the operator begins up and down movements, make sure that there are no personnel inside the danger zone. When, due to operational reasons, the lift is stopped at relatively low elevations (lower than 1.75m above the ground) personnel must be careful to avoid impact with parts of the machine not marked with special colors.

Risk of falling (vehicle)

This hazard may arise in the case of incorrect positioning of the vehicle on the platforms, overweight of the vehicle, or in the case of vehicles of dimensions that are not compatible with the capacity of the lift.

When the platform is being tested, the vehicle engine can not be turned on.

There is nothing should be placed on the lift-lowering area and the movable parts of the lift.

Risk of slipping

The floor caused by lubricant contamination of around the lift. The area beneath and immediately surrounding the lift and also the platforms must be kept clean. Remove any oil spills immediately.

Risk of electric shock

Risk of electric shock in areas of insulated and shattered electric equipments

Do not use jets of water, steam solvents or paint next to the lift, and take special care to keep such substances clear of the electrical control panel.

Risks related to appropriate lighting

The operator and the maintenance fitter must be able to assure that all the areas of the lift are properly and uniformly illuminate compliance with the laws in force in the place of installation.

During up and down operations, the operator should continually observe the lift and can operate it only in the position of operator. When lifting and lowering the vehicle, the cushion needs being put in the bottom of chassis.

The handling of safety devices is strictly forbidden. Never exceed the maximum carrying capacity of the lift, make sure the vehicles to be lifted have no load.

It is therefore essential to adhere scrupulously to all regulations regarding use, maintenance and safety contained in this manual.

High quality scissor lifts are on promotion now, detailed product information, pls refer to our website http://www.chinapuli.com/Lift/Scissor-Lift/.

2016年8月15日星期一

PL-1120 Wheel Balancer Operation Video

PL-1120 Wheel Balancer Operation Video

https://youtu.be/s5RUVjZSbdU

For more details of PL-1120 wheel balancer, pls click http://www.chinapuli.com/Middle-Class-Wheel-Balancer/PL-1120-Wheel-Balancer.html

https://youtu.be/s5RUVjZSbdU

For more details of PL-1120 wheel balancer, pls click http://www.chinapuli.com/Middle-Class-Wheel-Balancer/PL-1120-Wheel-Balancer.html

2016年8月11日星期四

PL-2960 Truck Tire Changer Operation Video

| PL-2960 Truck Tire Changer Operation Video https://youtu.be/Gg08w9-WHjo |

2016年8月3日星期三

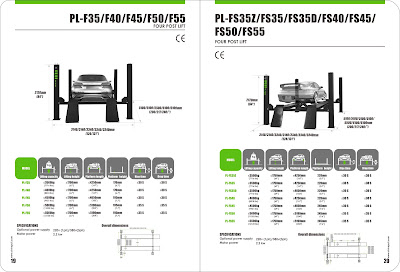

High Quality Four Post lifts

Being the nation's leading 4 post lift manufacturers--PULI. We also offer our value priced line of 4 post lifts exclusively from Auto Lift. Our four post lifts range in lifting capacity from 7,716 lbs. - 11,023 lbs. Check out our catalog!

For details on our four post lifts, please visit our 4 post lifts page.

http://chinapuli.com/Four-Post-Lift/

For details on our four post lifts, please visit our 4 post lifts page.

http://chinapuli.com/Four-Post-Lift/

2016年7月28日星期四

Scissor Lift for Wheel Alignment Introduction

Scissor Lift for Wheel Alignment Introduction

http://chinapuli.com/Lift/Scissor-Lift/PL-D35B-Scissor-Lift.html

http://chinapuli.com/Lift/Scissor-Lift/PL-D35B-Scissor-Lift.html

2016年7月25日星期一

Two Post Lift

Below are some of the two post lifts we carry at GUANGZHOU JINGJIA AUTO

EQUIPMENT. Check out the items below or browse the site (www.chinapuli.com) for

any other automotive equipment you might need!

PL-3.5-2B Two Post Lift

The PL-3.5-2B is with floor plate. It's the perfect choice for those customers

who demand the 3500kg lifting capacity at the lowest possible price. The

minimum height of the lifting pad of PL-3.5-2B is 110mm, easily lift and

suitable for low profile cars and SUV.

PL-4.0-2B Two Post Lift

The PL-4.0-2B is the upgrade version of the PL-3.5-2B two post above ground

lift. The PL-4.0-2B lifting capacity is 4000kg, 500 kg bigger than PL-3.5-2B.

The PL-4.0-2B is a commercial grade two post lift and is the perfect choice for

those commercial garages or homeowner who demands the high quality at the

absolute best price. The PL-4.0-2B is a TRUE 8,840 lb. capacity 2 post lift

that offers a great value to the customer.

EQUIPMENT. Check out the items below or browse the site (www.chinapuli.com) for

any other automotive equipment you might need!

PL-3.5-2B Two Post Lift

The PL-3.5-2B is with floor plate. It's the perfect choice for those customers

who demand the 3500kg lifting capacity at the lowest possible price. The

minimum height of the lifting pad of PL-3.5-2B is 110mm, easily lift and

suitable for low profile cars and SUV.

PL-4.0-2B Two Post Lift

The PL-4.0-2B is the upgrade version of the PL-3.5-2B two post above ground

lift. The PL-4.0-2B lifting capacity is 4000kg, 500 kg bigger than PL-3.5-2B.

The PL-4.0-2B is a commercial grade two post lift and is the perfect choice for

those commercial garages or homeowner who demands the high quality at the

absolute best price. The PL-4.0-2B is a TRUE 8,840 lb. capacity 2 post lift

that offers a great value to the customer.

2016年7月21日星期四

Motorcycle Tire Changer

Here at GUANGZHOU JINGJIA AUTO EQUIPMENT, we always like to help with all your automotive needs. We present the PL-1206 Tire Changer, the perfect tire changer for a commercial garage or for your motorcycles.

Visit www.chinapuli.com for more information.

Visit www.chinapuli.com for more information.

2016年7月18日星期一

Car Lift Safety Features

There’s no one way to make a car lift or truck lift safer for the operator. Manufacturers of high-quality automotive lifting products are always looking for better, more secure lifting methods. As a result, many excellent automotive lift safety features are now offered to the consumer. Here are just a few examples of the great technological strides that reputable CE certification partners have developed to keep you and your employees safe.

Two-post Car Lift Automatic Arm Restraints

Because the various car lifting solution designs can be extremely different from each other, it makes sense that some safety features are specific to only one kind of car lift. Two-post car lifts employ swing arm assemblies that allow the operator to change the arm configuration to suit a wide range of vehicles. It is important that swing arm lifts employ restraint devices to prevent arms from shifting or dislodging after a car or truck is already mounted and raised. Higher-quality two-post car lifts will feature this safety critical element; typically a gear mechanism that automatically secures the arms into place whenever the lift begins to rise. The automatic gear arm restraints will only disengage again when the lift is in a safe, lowered state. Because this process is automatic, the operator does not need to worry about forgetting to secure the arms.

Four-Post Car Lift Anti-Sway Blocks

Four-post car lifts are principally suspension lifts that rely on their columns to contain the lifting structure via cables or chains, while simultaneously bearing the load equally between them. Since the four-post car lift is not a rigid structure, it was once common for lifts to sway slightly during raising or lowering operations. Anti-sway blocks are one method of minimizing sway and maintaining proper spacing. This is especially important to ensure that safety locks are always engaged and that each post or column is holding 1/4th of the overall weight.

Four-Post Car Lift Runway Ramps and Chocks

Be sure your auto lift is equipped with manual wheel chocks as the primary means to restrain vehicles from inadvertently rolling off either end of the runways. Automatic stops on the approach end and fixed stops up front should be provided on runway lifts as a secondary means to restraint.

Hydraulic Flow Restrictor

Hydraulic car lifts that are designed with safety in mind use specialized hydraulic flow restrictors or velocity fuses integrated into the hydraulic cylinders or hydraulic circuit to control sudden, rapid decent in the event of a hydraulic component failure. These essential safety devices can dramatically reduce or stop downward travel in a free-fall situation due to a hydraulic system failure other than the cylinders themselves. When exploring lifting solutions, always make sure the car lift design features these crucial components for consistently smooth operation and no surprises.

Design That Address and Eliminates Pinch Points

Pinch points are not just mere annoyances like the name might suggest. Without supervision and careful operation, pinch points can result in damaged property and injury. Reputable manufacturers employ engineers to help identify potential pinch points for hoses and limbs, and then they remove them from the design of an auto lift.

Automatic Safety Locks

These powerful load-holding devices automatically engage and lock the lift structure as the car lift raises, preventing sudden free fall in the unlikely event of a suspension component failure. Typically, after the lift is raised to the required working height, operators are instructed to lower the lift until it is resting safely on the locks to minimize wear on suspension components. Once the locks are engaged, the car lift has to be raised slightly in order to release the safety locks. The better car lifts on the market often have locks spaced no more than five inches apart to better protect operators or bystanders. Load-holding devices should always require an independent and positive action for release, and they should always engage and reset automatically each time the lift is raised.

Slack Cable or Slack Chain Device Safety Device

As a redundant safety precaution, all professional-grade car lifts that employ either cable or chain suspension methods should incorporate a slack cable or chain device. These slack cables act as an automatic brake for the supported structure if a suspension component breaks or slackens.

Safe Systems and Procedures

When searching for a car lift, always ensure the manufacturer has a written quality assurance system of policies and procedures that are implemented and managed by quality control personnel. Safety policies and procedures should embrace safety specific subjects like organization, functions, duties and authority; policy and procedure publication, change control and record keeping; engineering drawing and specification publication, change control and record keeping; manufacturing process conformance determination, change control and record keeping; raw material and purchased part conformance determination and record keeping; component and end item conformance testing and record keeping; calibration and record keeping and traceability to the National Institute of Standards and Technology (NIST), or other national standards, for all gauges, measuring devices, tools and instruments that affect the quality of the final product; and, control and disposition of nonconforming material.

Specialized Lifting Pads for Different Types of Vehicles

Make sure you always have the right tool for every lifting job. Vans and trucks require different adapters than cars and motorcycles. The dealer or manufacturer should have a variety of options and accessories to help customize your automotive lift to fit your specific auto lifting needs. If they don’t, take it as a sign that their car lifting products might lack the proper support.

Proper Use and Safety Instructions

Always be sure that your car lift is supplied with operation, inspection, service and maintenance instructions that include specifications of the lift, lift rated load capacity, significant lift and bay dimensions, power requirements (compressed air and/or electrical), foundation and floor structural requirements. Car lift installation instructions should be clear with graphics illustrating full step-by-step assembly, exploded drawings with part numbers and descriptions, component packing list, site requirements, mounting and anchoring instructions, recommended clearance around and above lift, plan and elevation details of auto lift layout, final pre-check procedure for assembled lift, operational test & inspection and maintenance instructions.

Labeling

To raise safety awareness for all operators and bystanders, auto lifts should always include pertinent warning labels, as well as raising and lowering instructions. These labels shall be located at the point of hazard so that they will be plainly visible by the operator when he or she is in position to raise or lower the car lift’s load.

professional car lifts manufacturer, automotive lift wholesale: http://www.chinapuli.com/Lift/

Two-post Car Lift Automatic Arm Restraints

Because the various car lifting solution designs can be extremely different from each other, it makes sense that some safety features are specific to only one kind of car lift. Two-post car lifts employ swing arm assemblies that allow the operator to change the arm configuration to suit a wide range of vehicles. It is important that swing arm lifts employ restraint devices to prevent arms from shifting or dislodging after a car or truck is already mounted and raised. Higher-quality two-post car lifts will feature this safety critical element; typically a gear mechanism that automatically secures the arms into place whenever the lift begins to rise. The automatic gear arm restraints will only disengage again when the lift is in a safe, lowered state. Because this process is automatic, the operator does not need to worry about forgetting to secure the arms.

Four-Post Car Lift Anti-Sway Blocks

Four-post car lifts are principally suspension lifts that rely on their columns to contain the lifting structure via cables or chains, while simultaneously bearing the load equally between them. Since the four-post car lift is not a rigid structure, it was once common for lifts to sway slightly during raising or lowering operations. Anti-sway blocks are one method of minimizing sway and maintaining proper spacing. This is especially important to ensure that safety locks are always engaged and that each post or column is holding 1/4th of the overall weight.

Four-Post Car Lift Runway Ramps and Chocks

Be sure your auto lift is equipped with manual wheel chocks as the primary means to restrain vehicles from inadvertently rolling off either end of the runways. Automatic stops on the approach end and fixed stops up front should be provided on runway lifts as a secondary means to restraint.

Hydraulic Flow Restrictor

Hydraulic car lifts that are designed with safety in mind use specialized hydraulic flow restrictors or velocity fuses integrated into the hydraulic cylinders or hydraulic circuit to control sudden, rapid decent in the event of a hydraulic component failure. These essential safety devices can dramatically reduce or stop downward travel in a free-fall situation due to a hydraulic system failure other than the cylinders themselves. When exploring lifting solutions, always make sure the car lift design features these crucial components for consistently smooth operation and no surprises.

Design That Address and Eliminates Pinch Points

Pinch points are not just mere annoyances like the name might suggest. Without supervision and careful operation, pinch points can result in damaged property and injury. Reputable manufacturers employ engineers to help identify potential pinch points for hoses and limbs, and then they remove them from the design of an auto lift.

Automatic Safety Locks

These powerful load-holding devices automatically engage and lock the lift structure as the car lift raises, preventing sudden free fall in the unlikely event of a suspension component failure. Typically, after the lift is raised to the required working height, operators are instructed to lower the lift until it is resting safely on the locks to minimize wear on suspension components. Once the locks are engaged, the car lift has to be raised slightly in order to release the safety locks. The better car lifts on the market often have locks spaced no more than five inches apart to better protect operators or bystanders. Load-holding devices should always require an independent and positive action for release, and they should always engage and reset automatically each time the lift is raised.

Slack Cable or Slack Chain Device Safety Device

As a redundant safety precaution, all professional-grade car lifts that employ either cable or chain suspension methods should incorporate a slack cable or chain device. These slack cables act as an automatic brake for the supported structure if a suspension component breaks or slackens.

Safe Systems and Procedures

When searching for a car lift, always ensure the manufacturer has a written quality assurance system of policies and procedures that are implemented and managed by quality control personnel. Safety policies and procedures should embrace safety specific subjects like organization, functions, duties and authority; policy and procedure publication, change control and record keeping; engineering drawing and specification publication, change control and record keeping; manufacturing process conformance determination, change control and record keeping; raw material and purchased part conformance determination and record keeping; component and end item conformance testing and record keeping; calibration and record keeping and traceability to the National Institute of Standards and Technology (NIST), or other national standards, for all gauges, measuring devices, tools and instruments that affect the quality of the final product; and, control and disposition of nonconforming material.

Specialized Lifting Pads for Different Types of Vehicles

Make sure you always have the right tool for every lifting job. Vans and trucks require different adapters than cars and motorcycles. The dealer or manufacturer should have a variety of options and accessories to help customize your automotive lift to fit your specific auto lifting needs. If they don’t, take it as a sign that their car lifting products might lack the proper support.

Proper Use and Safety Instructions

Always be sure that your car lift is supplied with operation, inspection, service and maintenance instructions that include specifications of the lift, lift rated load capacity, significant lift and bay dimensions, power requirements (compressed air and/or electrical), foundation and floor structural requirements. Car lift installation instructions should be clear with graphics illustrating full step-by-step assembly, exploded drawings with part numbers and descriptions, component packing list, site requirements, mounting and anchoring instructions, recommended clearance around and above lift, plan and elevation details of auto lift layout, final pre-check procedure for assembled lift, operational test & inspection and maintenance instructions.

Labeling

To raise safety awareness for all operators and bystanders, auto lifts should always include pertinent warning labels, as well as raising and lowering instructions. These labels shall be located at the point of hazard so that they will be plainly visible by the operator when he or she is in position to raise or lower the car lift’s load.

professional car lifts manufacturer, automotive lift wholesale: http://www.chinapuli.com/Lift/

2016年7月12日星期二

2016年7月10日星期日

Heavy-Duty Tire Changers

These heavy-duty truck tire changers are strong! These changers usually have to deal with heavy-duty tires. The PL-2980 handles tire diameters up to 98” and rims between 14” and 56”.

Be careful when choosing a heavy-duty tire changer, some are made especially for agricultural, off-road and constructional vehicles and other are designed

especially for businesses that maintain a fleet of vehicles. These are great for truck shops, but if you’re not working on large tires, we don’t recommend owning one of these.

For more product details, pls refer to http://www.chinapuli.com/Truck-Tire-Changer/PL-2980-Tyre-Changer.html.

2016年7月8日星期五

How to choose best tire changer?

When selecting a tire changer you must make sure the wheel clamping ability is large enough to service the size of wheels you intend on working with, if you are considering a jaw clamping design make sure the external clamping range is adequate, most manufactures of tire changers list the internal clamping capacity, however to clamp aluminum wheels without any visible damage, or to clamp a reverse drop center rim you should clamp them externally. A rim with a reverse drop center will need to be mounted up side down to keep the drop center closer to the top bead.

The next consideration should be the outside tire capacity of the changer, the upright column that supports the swing arm for the mounting head needs to be mounted far enough back to allow the overall diameter of the tire to clear. If you intend on changing larger truck tires this will need to accommodate up to a 35" tire or even larger.

Consider a tire changer with an air assist arm if you are going to work with low profile tires, the assist arm should have the ability to follow the tire as it rotates to assist in holding the tire bead in the drop center of the rim to allow mounting the tire without damaging the tire bead. The arm should be equipped with an adapter to allow the rim to be depressed downward while clamping to allow the rim to be clamped externally without damage.

The side shovel to break down the bead should have the capacity of the largest wheel you will be servicing, some truck and performance wheels get very wide.

Other options and features to be considered are :

Motor size to provide enough torque to service low profile and truck tires.

Mount/dismount head design, make sure polymer inserts are available or a polymer head is available.

Tire clamping jaws have protective covers available for rim protection or choose a center clamping design that will not damage the wheel.

The inflation system is capable of inflating all types of rims, the inflation jets must be properly aimed at the tire bead, some new changers are equipped with a blast type inflation that is similar to the Cheetah air inflation system.

The bead lever design can make a difference when changing low profile tires, some new style tire changers offer lever less tool heads, a pneumatic lever flips down to reach under the bead for ease of dismounting.

Service, make sure there is service available for the tire changer you select, many of the imported units have no parts available for servicing the tire changer in the future.

professional tire changer supplier, factory price tire changer:http://www.chinapuli.com/Tyre-Changer/

The next consideration should be the outside tire capacity of the changer, the upright column that supports the swing arm for the mounting head needs to be mounted far enough back to allow the overall diameter of the tire to clear. If you intend on changing larger truck tires this will need to accommodate up to a 35" tire or even larger.

Consider a tire changer with an air assist arm if you are going to work with low profile tires, the assist arm should have the ability to follow the tire as it rotates to assist in holding the tire bead in the drop center of the rim to allow mounting the tire without damaging the tire bead. The arm should be equipped with an adapter to allow the rim to be depressed downward while clamping to allow the rim to be clamped externally without damage.

The side shovel to break down the bead should have the capacity of the largest wheel you will be servicing, some truck and performance wheels get very wide.

Other options and features to be considered are :

Motor size to provide enough torque to service low profile and truck tires.

Mount/dismount head design, make sure polymer inserts are available or a polymer head is available.

Tire clamping jaws have protective covers available for rim protection or choose a center clamping design that will not damage the wheel.